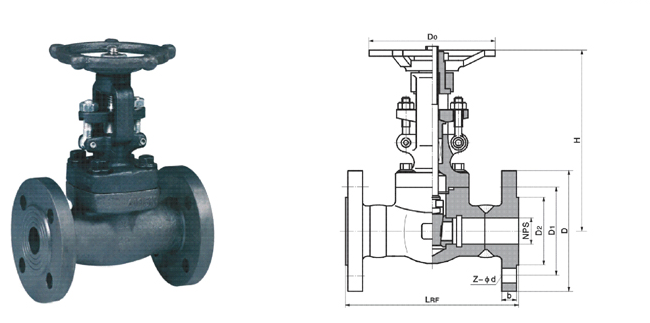

API forged steel gate valve

API forged steel gate valve

Nominal diameter: DN10 ~ 50mm

Nominal: PN2.5,4.0,10.0,14.0,25.0Mpa

Suitable medium: water, nitrogen-hydrogen mixed gas, urea and methylamine solution, etc.

Connection: flange connection, and an internally threaded socket weld connection

design and manufacturing: ANSIB16.34 API600 API602

flange dimensions: ANSIB16.5

First, American Standard forged steel gate valve structural features:

1, forged steel valves for nominal pressure PN2.5,4.0,10.0,14.0,25.0Mpa, the nominal diameter of DN10 ~ 50mm high-temperature, high-pressure valve. Applicable medium for water, nitrogen and hydrogen mixed gas, urea and methylamine liquid.

2, stem and stem nut for the trapezoidal thread drive, thread in line with the provisions of GB5796. Stool head design with a tapered upper sealing surface, when the valve is fully open with the valve cover on the tight seal, no leakage.

3, the valve body, bonnet and other pressure parts using the overall forging (tire model forging), the valve body flange can also be used in the form of welding. The connection of the valve is in the form of a flange connection, a socket connection and an internal thread connection.

4, the valve seat and the valve body connection has a screw connection, welding, in the valve body on the surfacing alloy layer or stainless steel valve directly from the valve body processing. Surfacing layer thickness greater than or equal to 2mm.

5, for the nominal pressure greater than 15.0Mpa forged steel valve pressure from the tight seal structure, packing boxes and gate are used for the overall forging processing to ensure compression strength.

Second, the American Standard forged steel gate valve design and manufacturing standards:

1, design and manufacture: ANSIB16.34 API600 API602

2, flange size: ANSIB16.5

3, the pressure temperature: ANSIB1.20.1

4, the length of the structure: ANSIB16.10

5 , Butt welding connection size: ANSIB16.11

6, inspection and testing: API598

Third, American Standard forged steel gate valve Product Material:

Serial number | Part Name | CS to ASTM | AS to ASTM | SS to ASTM | |

| Type A105 | Type F22 | Type F304 (L) | Type F316 (L) | ||

| 1 | Body | A105 | A182 F22 | A182 F304 (L) | A182 F316 (L) |

| 2 | Seat | A276 420 | A276 304 | A276 304 (L) | A276 316 (L) |

| 3 | gate | A276 410 & 430 | A182 F304 | A182 F304 (L) | A182 F316 (L) |

| 4 | Stem | A182 F6 | A182 F304 | A182 F304 (L) | A182 F316 (L) |

| 5 | Gasket | Corrugated SS + graphite | SS + PTFE | ||

| 6 | cap | A105 | A182 F22 | A182 F304 (L) | A182 F316 (L) |

| 7 | bolt | A193 B7 | A193 B16 | A193 B8 | A193 B8M |

| 8 | Pin | A276 420 | A276 304 | ||

| 9 | Packing sleeve | A276 410 | A182 F304 (L) | A182 F316 (L) | |

| 10 | Living bolts | A193 B7 | A193 B16 | A193 B8 | A193 B8M |

| 11 | Packing plate | A105 | A182 F11 | A182 F304 (L) | A182 F316 (L) |

| 12 | Nuts | A194 2H | A194 4 | A194 8 | A194 8M |

| 13 | Stem nut | A276 420 | |||

| 14 | fasten the screw nut | A194 2H | A194 4 | A194 8 | A194 8M |

| 15 | Nameplate | SS | |||

| 16 | Hand wheel | A197 | |||

| 17 | Lubricating gaskets | A473 431 | |||

| 18 | filler | Flexible Graphite | PTFE | ||

| Applicable media | Water, steam, oil and so on | Water, steam, oil and so on | Nitric acid, acetic acid and so on | ||

| proper temperature | -29 ° C to 425 ° C | -29 ° C to 550 ° C | -29 ° C to 180 ° C | ||

Note: Other materials available to customers are also available. Seal fabric pairing is determined by the customer's designation. CS = carbon steel; AS = alloy steel; SS = stainless steel

Four, American Standard forged steel gate valve connection size:

ANSI 150Lb | ||||||||

NPS | And rounds.itherters nights | 3/8 | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 |

L | - | - | 108 | 117 | 127 | 140 | 165 | 178 |

L1 | 79 | 79 | 79 | 92 | 111 | 120 | 120 | 140 |

H | 169 | 169 | 169 | 193 | 230 | 246 | 283 | 330 |

D0 | 100 | 100 | 100 | 100 | 125 | 160 | 160 | 180 |

Wt | - | - | 5 | 6.1 | 8.4 | 14.3 | 15.4 | 22.7 |

Wt1 | 2.2 | 2.4 | 2.4 | 2.4 | 4.8 | 6.1 | 7.2 | 11.2 |

ANSI 300Lb | ||||||||

NPS | And rounds.itherters nights | 3/8 | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 |

L | - | - | 140 | 152 | 165 | 178 | 190 | 216 |

L1 | 79 | 79 | 79 | 92 | 111 | 120 | 120 | 140 |

H | 169 | 169 | 169 | 193 | 230 | 246 | 283 | 330 |

D0 | 100 | 100 | 100 | 100 | 125 | 160 | 160 | 180 |

Wt | - | - | 5.2 | 6.3 | 8.6 | 14.5 | 15.6 | 22.8 |

Wt1 | 2.2 | 2.4 | 2.4 | 2.4 | 4.8 | 6.1 | 7.2 | 11.2 |

ANSI 600Lb | ||||||||

NPS | And rounds.itherters nights | 3/8 | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 |

L | - | - | 165 | 190 | 216 | 229 | 241 | 292 |

L1 | 79 | 79 | 79 | 92 | 111 | 120 | 120 | 140 |

H | 169 | 169 | 169 | 193 | 230 | 246 | 283 | 330 |

D0 | 100 | 100 | 100 | 100 | 125 | 160 | 160 | 180 |

Wt | - | - | 5.9 | 7.5 | 10.2 | 16.7 | 17.4 | 28.7 |

Wt1 | 2.2 | 2.4 | 2.4 | 2.4 | 4.8 | 6.1 | 7.2 | 11.2 |

ANSI 800Lb | ||||||||

NPS | And rounds.itherters nights | 3/8 | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 |

L1 | 79 | 79 | 79 | 92 | 111 | 120 | 120 | 140 |

H | 169 | 169 | 169 | 193 | 230 | 246 | 283 | 330 |

D0 | 100 | 100 | 100 | 100 | 125 | 160 | 160 | 180 |

Wt1 | 2.2 | 2.4 | 2.4 | 2.4 | 4.8 | 6.1 | 7.2 | 11.2 |

Zhejiang public security reserve No. 33032402001552

Zhejiang public security reserve No. 33032402001552